Some users online have shared that after assembling a particular brand of figurine they purchased, their hands started to feel a stinging pain, became red and swollen, and even developed skin lesions, forcing them to seek medical attention. They suspects that the figurine’s components contain fiberglass. But is fiberglass really that dangerous? We’ll get into that later. In the meantime, let’s take this opportunity to share some knowledge about toy materials.

Just a quick disclaimer: I’m not an expert in materials science, so if there are any inaccuracies, I welcome corrections!

Plastic Toys

In the world of toys, plastic is the most commonly used material.

As a material with both praise and criticism, some people see it as a revolutionary force in industrial manufacturing and daily life, while others associate it with being a harmful chemical substance. However, with advancements in technology, plastics have been subdivided into numerous types, and many of the plastics used in toy manufacturing now feature health-conscious and environmentally friendly properties.

ABS

ABS – composed of acrylonitrile, butadiene, and styrene – is a plastic known for its high hardness and toughness, excellent dimensional stability, high precision in finished products, ease of coloring, resistance to high and low temperatures, and durability against wear and impact. LEGO bricks, for example, widely use ABS plastic due to these properties. (LEGO also uses other types of materials for specific applications.)

However, this material comes at a high cost. Producing just one kilogram of ABS requires approximately two kilograms of petroleum, making it a choice that only brands with substantial resources can afford. LEGO Group, for instance, is actively seeking alternatives to replace ABS due to its energy-intensive production process. Additionally, ABS is not UV-resistant; prolonged exposure to sunlight can cause it to fade and become brittle, making it unsuitable for long-term outdoor use.

PVC

PVC – polyvinyl chloride – is a lightweight material known for its heat insulation, thermal preservation, moisture resistance, flame retardancy, and ease of processing. Combined with its low cost, PVC has become one of the most widely used materials in plastic toys.

However, PVC has relatively weak resistance to high temperatures and UV rays. Exposure to higher temperatures can cause toys to discolor, while prolonged sunlight exposure can make them brittle over time.

It’s worth mentioning that PVC can be blended with ABS to create a new material that combines the durability of ABS with the cost-effectiveness of PVC. This hybrid material is currently used by many brands for mass-producing trendy blind box collectibles.

PP

PP – polypropylene plastic – is a non-toxic, odorless material that can withstand immersion in boiling water at 100°C without deforming or degrading. It is also highly resistant to common acids, bases, and organic solvents.

Because of these properties, it is often used to make rattles, teething toys, and other toys designed for young children that may be put in their mouths. However, under high-temperature conditions, polypropylene softens, burns, and can release toxic gases such as carbon monoxide. Therefore, it should always be kept away from open flames.

PE/EVA

PE/EVA – These two materials are commonly used in products like baby play mats. PE (polyethylene) has better cold resistance but is more flammable. EVA (ethylene-vinyl acetate) is less flammable and more resistant to dirt. However, during production, recycled materials are often used, and toxic additives may sometimes be included in the manufacturing process.

TPR

TPR – thermoplastic rubber – is essentially an extension of soft PVC resin, compressed to form a rubber-like material. It is safe and non-toxic, making it suitable for toys like balls or teething rings. However, it doesn’t have high temperature resistance and should not be boiled in hot water.

Si-TPV

Si-TPV – This is a new material made by combining silicone with plastic, and it is an eco-friendly foam plastic that has been introduced in recent years. It is not only non-toxic and odorless but also 100% recyclable.

Some of the phone cases we use are made from this material, and many toy products are beginning to incorporate it as well. However, Si-TPV is relatively expensive to produce, difficult to process and has poor resistance to extreme high and low temperatures.

EPP

EPP – Expanded polypropylene – is an eco-friendly plastic with excellent heat resistance and low-temperature cushioning properties.

Due to its strong and durable nature, it doesn’t fatigue with repeated use, making it ideal for products like foam airplanes or large building blocks for children’s castles. However, it may crack under heavy impact, and its production cost is relatively high.

PC

PC – polycarbonate – is a widely used plastic material, commonly found in items like baby bottles and space cups.

However, it has received criticism because it can release bisphenol A (BPA), a substance that is harmful to human health when exposed to high temperatures. As a result, this material should not be heated or exposed to direct sunlight.

Wooden Toys

Before the invention of plastic, wood was the material of choice for most toys due to its strong plasticity and durability. In fact, LEGO originally built its brand reputation with various wooden toys.

As a natural, non-toxic, and environmentally friendly material, wooden toys are still widely appreciated today. However, some low-quality products may use adhesives, flame retardants, or other chemicals that contain harmful substances like polycyclic aromatic hydrocarbons (PAHs) and formaldehyde. Therefore, it’s important to be cautious when purchasing wooden toys.

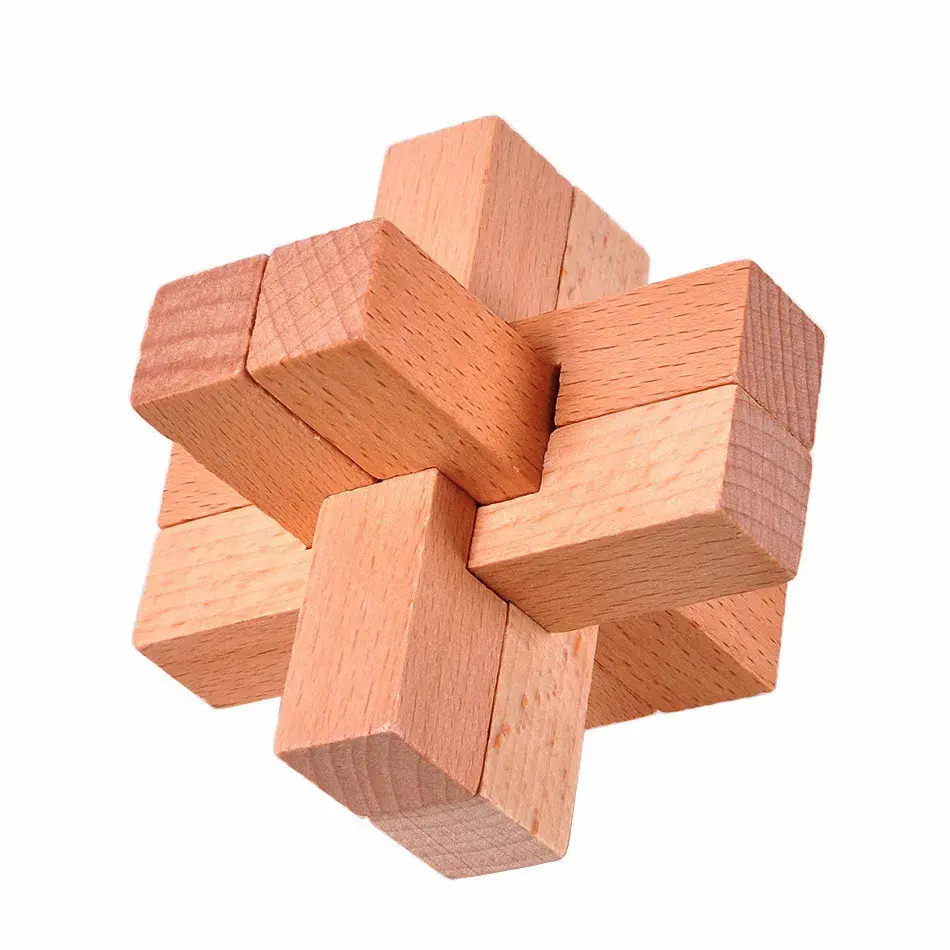

Beech Wood

Beech wood – In the world of toy manufacturing, beech wood holds the highest regard. Its natural appearance, superior physical properties, and excellent workability make it a premium choice for wooden toys.

During the early days of LEGO, when funds were tight, the company still insisted on using beech wood for its wooden toys. Today, many renowned wooden toy brands, such as Sweden’s BRIO, Germany’s HABA and HEROS, and China’s MuWan Family, continue to use beech wood as a key material in their products.

However, beech wood is relatively expensive and requires specialized tools and craftsmanship for processing. It is also prone to cracking and warping in humid environments, so proper care and protection are needed to extend its lifespan.

Basswood

Basswood – This wood is widely used in toy production, with many common items like bead mazes and baby walkers primarily made from linden wood.

It is not only durable, corrosion-resistant, and fire-retardant, but also has a naturally beautiful grain, making it an ideal material for toys. While it is slightly less expensive than beech wood, its hardness does increase manufacturing costs. Additionally, linden wood has poor resistance to insects, so improper storage can lead to damage from pests.

Linden wood

Linden wood – This wood is abundant in northeastern China and Russia, where it is commonly used to make the famous Russian nesting dolls (matryoshka).

Linden wood is highly flexible, durable, corrosion-resistant, and less prone to cracking, making it easy to work with. However, it is sensitive to moisture, has poor resistance to steam bending, and is not ideal for crafting toys with complex shapes.

Pine Wood

Pine wood – This wood is inexpensive and suitable for mass production, but it is prone to moisture, pest damage, and imperfections like knots, which can affect its appearance.

As a result, pine is typically used as a secondary material or for specific parts in toy manufacturing, rather than as the main material for the entire toy.

Birch Wood

Birch wood – Known for its high compressive and bending strength, birch wood products are extremely durable. Additionally, its fine grain and light yellow or white color give it a warm, clean appearance.

As a fast-growing tree species, birch is also relatively cost-effective. However, it is sensitive to changes in humidity, which can cause it to warp or crack, so proper storage is necessary to maintain its quality.

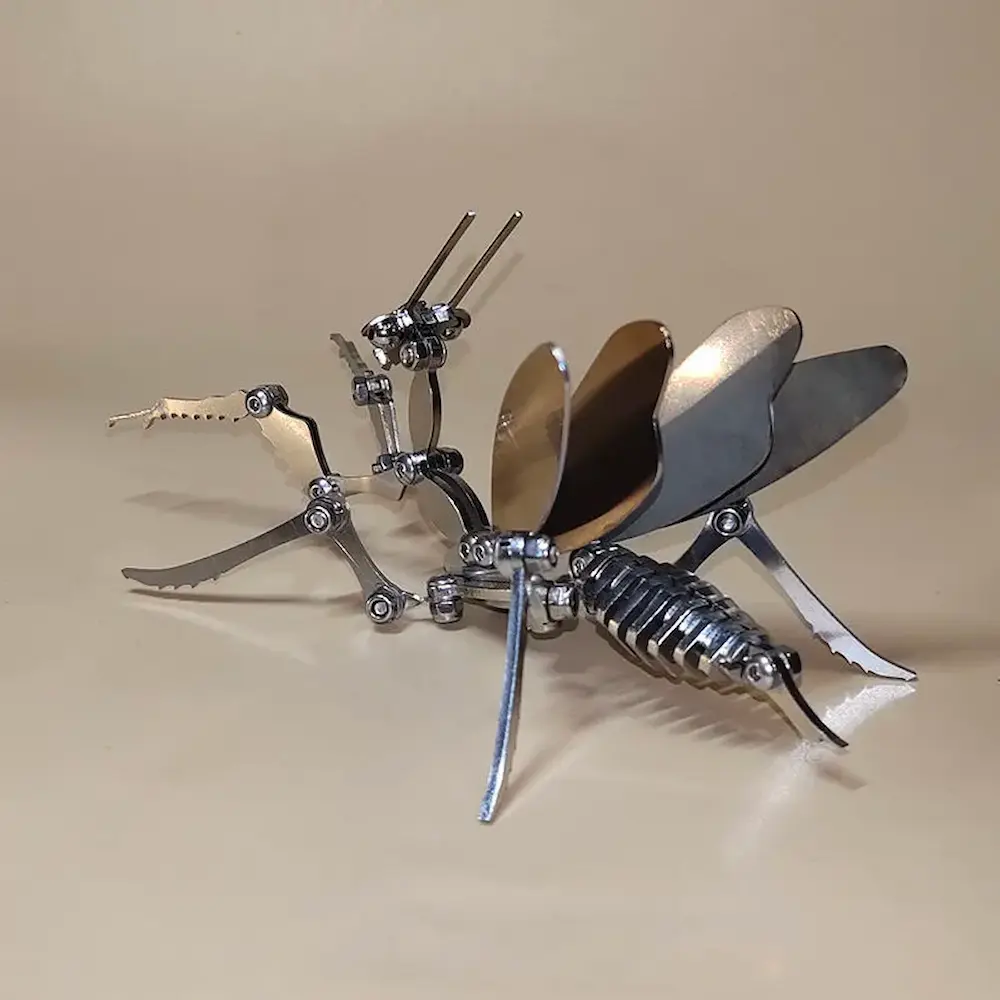

Metal Toys

Metal has a beautiful shine and solid texture, and toys made from metal have a unique quality in both their lines and feel that can’t be matched by other materials.

While processes like stamping, casting, and welding can be more expensive, the malleability of metal allows for greater precision in models and figurines, resulting in better detail and accuracy. However, the relative heaviness of metal, along with its tendency to expand and contract with temperature changes and its susceptibility to rust, means it can’t be widely used across all toy categories.

Stainless Steel

Stainless steel – Stainless steel is known for its high strength and corrosion resistance. It’s durable, resistant to rust and breakage, and has a smooth surface that resists dirt, making it ideal for making toys like car models and hand bells that need to withstand heavy play.

However, stainless steel is expensive in terms of both material and manufacturing processes. Additionally, its appearance tends to have a cold, industrial feel, lacking the warmth that other materials might offer.

Aluminum alloy

Aluminum alloy – Aluminum alloy offers high strength and corrosion resistance, but it’s also lighter than other metals, making it ideal for producing toys like figures, animals, and vehicles.

However, its manufacturing costs are relatively high, and since aluminum alloys contain heavy metals, surface treatments like painting and plating may leave behind toxic substances.

Zinc Alloy

Zinc alloy – Zinc alloy has excellent casting properties and can be die-cast into complex, thin-walled precision parts, making it ideal for creating toys in various shapes. It also supports a range of surface treatments, enhancing the toy’s appearance.

The well-known toy car brand, Matchbox, extensively uses zinc alloy in its models. However, zinc alloy is not very corrosion-resistant, and if it contains high levels of aluminum or copper, it can be prone to rusting and paint chipping. Additionally, there are significant performance differences between different grades of zinc alloy. For example, grade 3 and grade 5 alloys are stronger, while grade 4 alloy is more prone to cracking.

Alloy

Alloy – Alloy materials aren’t as hard as other metals, but they can be die-cast into complex shapes, making them ideal for toys like mecha figures. However, toys made from alloys tend to be more expensive, and their painted surfaces and heavier weight may not be suitable for younger children.

Other Materials

PU Resin

PU Resin – Known as polyurethane, PU resin offers better stability, durability, and resilience compared to plastics like PVC. It has a pleasant feel, and excellent detail retention, and is ideal for creating figurines.

However, PU resin is relatively expensive and is typically used for small-scale production by artists. The finished products are also fragile, requiring careful packaging during transport.

Soft vinyl

Soft vinyl – This material is flexible and elastic, bouncing back quickly after being pressed. It’s easy to color and shape, and in Japan during the last century, it was widely used to make monster toys.

You can also find soft vinyl in everyday items, such as soft rubber coasters and fridge magnets.

Polyresin

Polyresin – Often referred to as artificial stone, polyresin has a texture similar to real stone, but it is primarily made of resin, aluminum powder, and other materials.

Polyresin is inexpensive, offers good hardness and heat resistance, and is commonly used to make anime figurines or statues. However, it is difficult to process, and the finished products are relatively brittle and prone to breakage.

The materials listed above are some of the most common in toy manufacturing. However, with increasing concern for the health and well-being of consumers, many well-known toy brands are continuously exploring more eco-friendly and sustainable materials.

The Development of LEGO Brick Materials

Since 2020, the LEGO Group has been working on replacing petroleum-based plastics with sustainable, “non-oil-based” materials for their bricks. However, LEGO has strict standards for factors like color, gloss, and the sound made when bricks snap together. Meeting these requirements while ensuring the materials are more eco-friendly and resource-efficient is no easy task.

To date, LEGO has tested over 600 different materials, with the proportion of recycled and bio-based materials steadily increasing. The company plans to fully replace petroleum-based plastics with new materials by 2030.

What is Fiberglass?

Returning to the incident mentioned at the beginning, what exactly is fiberglass?

Fiberglass is an inorganic, non-metallic material with excellent performance. It is made by melting six types of raw minerals—such as talc, quartz sand, limestone, dolomite, borocalcite, and boromagnesite—at high temperatures, then drawing, twisting, and weaving them into fibers. The diameter of a single fiber can be as small as a few micrometers. Due to its strong insulation, heat resistance, and corrosion resistance, fiberglass has a wide range of industrial applications.

Despite its many useful properties, fiberglass is often referred to as a “dangerous invention” by many. Due to its tiny, nearly invisible fibers and non-degradable nature, prolonged contact without protective equipment can cause damage to the eyes, skin, and respiratory system. In fact, fiberglass is even listed as a carcinogen by the International Agency for Research on Cancer (IARC), a branch of the World Health Organization.

When fiberglass comes into contact with the skin, it can cause a sharp, pinprick-like pain. If this happens, it’s important to quickly clean the affected area. Visible fibers can be gently removed with tweezers or by using medical adhesive tape to pull them off. If the problem persists, it’s crucial to seek medical attention to prevent these tiny, transparent fibers from embedding deeper into the skin or causing an infection.

Finally, a friendly reminder: when purchasing toy figurines or models, always buy from legitimate sources and trusted brands to ensure your safety and protect your legal rights.

JMBricklayer is a brand that specializes in selling Lego-compatible building block sets for ages 14 and up. Whether you are a novice, an enthusiast, a seasoned player, a reviewer, or a MOC designer, our doors are open for you!

Use coupon code A4XVY6VK to save 15% on all non-sale Items.

100 Responses

How To Enter (Both Required):

1. Let us know which type of material toys are most common in your home and what the experience with them. Or any other topic you want Samon to write about in detail.

2. Share this article on any of your social media platforms.

Giveaway prize:

1st Prize (2 winners): Random JMBricklayer product

2nd Prize (3 winners): 40% off discount code

Giveaway Details

1. The giveaway is open to participants worldwide.

2. The Event ends on January 17th.

3. Each comment earns you an extra entry. The more entries, the more chances to win!

4. Winners will be randomly selected and announced on January 18th.

5. To claim the prize, winners must provide proof of their social media share(a screenshot or link).

6. Comments will be checked for ads, displayed after backend review, usually within 12 hours.

My brother and I mostly played with LEGOs growing up because they were our most modular toys.

We could build whatever we wanted with them.

So I prefer plastic more because of that.

We mostly have Lego or duplo type (ABS primarily), but we have lots of kinds of toys. We love building together and expressing our imaginations

I think a good topic would be what sets your company might build next.. not only would there be all the amazing ides that you share but we could add in ideas for future sets.

it’s definitely a plastic toy

Plastic toys can be so versatile! Do you think their durability or design makes them more appealing? Would love to hear what stands out most about this one for you!

Mine are all plastic as they are all Jmbricklayer kits.

Jmbricklayer kits sound fun! Do you enjoy the building process or displaying the final creations more?

Mostly plastic with my Lego sets!

Lego sets are such classics! Do you prefer building original designs or following the instructions? It’s always fun to hear how others enjoy their Lego creations!

Plastic and wood toys

Having both plastic and wood toys gives such variety! Do you notice any differences in how they hold up or how kids interact with them?

Plastic and wood toys

Plastic and wood toys

Plastic and wood toys

Plastic and wood toys

I have plastica Toys… But willing to buy stainless steel and metallic toys

Stainless steel and metallic toys sound interesting! Are you drawn to their durability or design? Would love to hear what types you’re considering and why they appeal to you!

Well I’m always been the book reader type, so my “toys” are mostly made of paper.

Books entertain me no matter what but sometime a bricky building wouldn’t hurt.

Books are amazing companions! What’s your favorite genre? A bricky building does sound like a fun change—have you tried mixing stories with creative builds?

i have mostly plastic which to me is easier to clean and keep. i did have many wiiden tiys when i was younger.

Plastic toys are definitely low-maintenance! Do you feel wooden toys had a different charm or durability when you were younger? Would love to hear how they compare in your experience!

I have ever an equal amount of material as far as plastic, wood and metal. Plastic is all my building blocks, wood is things I love building with my 4 year old grandson when we aren’t building with building bricks and then metal as far as our Hot Wheel collection goes. Years ago like in the 40’s & 50’s most kids toys were made of metal and wood. But to keep cost down and safety is why I think they started making things with plastic.

That’s such a great mix of materials! Building with your grandson must be so special. Do you feel each material offers a unique experience? Loved your insight on the shift to plastic!

My toys were of plastic, but today as adult I know that for kids plastic may be toxic. My experience teached me that time and sun light degrade plastic and other materials. So given the opportunity I avoid plastic, rubber, fiberglass…I know for fact that is estimated we put each year in our body the same weight of a shaving blade in plastic thru the food. My son’s toys are electronics. I’d say a new kind of “plastic” is needed

Great points about plastic and its impact! A safer, sustainable material would be a game changer. How do you feel about alternatives like biodegradable toys or eco-friendly electronics for kids?

Plastic toys are most common in your home and we have had mostly good experiences with them.

Plastic toys are so versatile! What do you think makes them a hit in your home—durability, variety, or something else? Would love to hear about your favorite experiences with them!

We have a fair amount of plastic, but also have some wood and a good amount of metal. Or metal toys will probably been my great grandchild’s someday!!

It’s great that you’re thinking about the longevity of toys! Have you noticed if certain materials hold up better over time? It’d be interesting to hear others’ experiences with wood vs. metal.

Mostly plastic in the household!

Plastic is so common in many households! Have you found any eco-friendly alternatives that work well? It’d be great to hear how others are reducing plastic use in their homes!

Honestly not really, I see mainly plastic. I like and prefer wooden ones, they around now more than the 80’s & 90’s. That said the wooden ones are hard to find, if found it’s mainly for the littles & very costly.

Plastic toys for me are the best but definitely not the safest

It’s true, plastic can be tricky when it comes to safety. Have you looked into non-toxic, BPA-free options? It’d be interesting to hear what others use for safe, durable toys!

The safest toys are plastic ones

I much prefer wooden toys for my children, although we have a mix of everything.

Wooden toys are a great choice—so timeless! How do you feel they compare to plastic or metal in terms of durability? Would love to hear others’ thoughts on balancing different materials!

Plastic toys for me are the best.

I always preferred wood. I love the feel of natural material in my hands and I have always admired the craftsmanship.

I totally agree! There’s something special about the feel of wood and the artistry behind it. Do you have any favorite wooden toys or brands you recommend? I’d love to hear more!

I never had any particular brand of wooden toys as a favorite. We usually buy them at local markets from craftsmen who produce small batches of unique toys. When I was a kid, my favorite wooden toy was a dog that had wheels instead of paws and you could disassemble it into multiple pieces so it also worked as a puzzle.

That sounds like such a fun and creative toy! Local craftsman-made toys really do have that special charm. Do you think more toys with multi-functional designs like that could catch on today?

I think they would, but it really depends on whether kids are guided toward such toys. Many parents these days prefer to just give their kids a phone or a tablet to play with, rather than guiding them to be creative.

Though I have to admit that the plastic is very versatile when it comes to creating all kinds of toys and most of my toys/collectibles these days are made of plastic because it’s much cheaper than wood.

You’re right—plastic’s versatility and cost-effectiveness are hard to beat! Do you find that the quality holds up over time? It’d be interesting to hear how others balance affordability with durability.

It varies greatly… the cheap plastic cars, dolls and similar toys for small children usually don’t hold up over time and you can usually instantly recognize that such toys won’t last long based on how thin the plastic is. On the other hand, I used to have plastic building bricks (a Czech brand called Cheva) that survived my whole childhood and now they are passed from one kid to another in my extended family, holding up with no issue.

That’s a great point! Quality really varies with plastic toys. It’s interesting how certain brands, like Cheva, manage to stand the test of time. What do you think makes some plastic toys so durable?

I guess it’s about the type of plastic used… and also if the brand actually wants their toys to last. If you make a thin layer of the cheapest material, the toy is bound to break at some point.

I love the wood.

Wood really does have a special charm, doesn’t it? Do you prefer handmade or mass-produced wooden items? Would love to hear what you love most about it!

Wood seems safer and more durable than plastic. Metal can be heavy and sharp when broken.

I only build Lego and other alt bricks now, so they are all plastic.

I do have some old wooden toys, but I never played with them they just collected dust on my shelves.

I do have a small collection of metal hot wheels and matchbox cars, they’re definitely not as fun as building Lego cars.

Plastic Lego and other brick toys are my favourite by far, you get the satisfying experience to build them and display them in your collection.

It’s great how Lego and other bricks combine creativity and fun! Do you find you still gravitate toward specific materials as you collect? It’s interesting how different toys can evoke different experiences!

When the kids were smaller, they played with a lot of wooden and plastic toys. As they got older, plastic seemed to take over everything when it came to toys.

It’s interesting how kids’ preferences shift over time! Do you think plastic is more appealing as they grow, or is it just more accessible? I’d love to hear how others balance both materials!

safety toys

so wonderful toys

Absolutely, safety is key when choosing toys! Do you have any favorite safe toy brands or materials you trust? It’d be great to hear what others look for in safe, fun toys!

Plastic toys are most common for me, but I also have a couple wooden ones.

It’s a nice mix! Do you find the wooden toys hold up differently over time compared to plastic? I’d love to hear how others balance these two materials in their collections!

I am totally new to building and love it!

That’s awesome! Building is such a rewarding hobby. What kind of projects are you starting with? It’d be great to hear your experiences and tips as you dive into it!

We mainly have plastic and wood. We don’t have kids, though, so I don’t know how that would affect what we would get!

Plastic and wood are great options! If kids were in the mix, durability and safety might come into play. Have you found any particular pros/cons with plastic vs. wood so far?

I wonder why there aren’t more wooden and other material toys available. My guess is it’s not financially friendly therefore won’t sell. That leads to me to think if there are ways to make stuff cheaper but people aren’t willing to take a chance.

Great point! Wooden toys can be pricier due to production costs, but maybe there’s a market for affordable, eco-friendly options. What do you think could make these toys more accessible?

With toy manufacturers and companies working together to make it happen? It’s a gamble some to take? It’s a tough call too, with this economy taking chances isn’t that simple either

You’re right, it’s a tough call! In today’s economy, taking risks can feel daunting. But collaboration between companies could lead to some great innovations—sometimes the risk pays off!

Yes, totally agree with you. I like to believe it’s an option & not impossible.

I think the different type of metals; stainless steel toys would be cool to be more common among toys(older children), then it would more likely end up as displays carrying the memories over as ones child becomes an adult. And the extras could easly get recycled ofcourse if not wanted.

Stainless steel toys could definitely make lasting keepsakes! They’re durable and eco-friendly too. Do you think they’d be a hit with kids, or more as collectible pieces for adults?

With both. Kids do very well with cars & trains, would be great to keep adding more and that’ll carry over to as collectibles as they get older being more appropriated filled with memories of there childhood as well 🙂

I totally agree! Cars and trains are timeless, and as kids grow, those toys can become cherished collectibles with great memories. It’s such a fun way to keep nostalgia alive! What do you think?

Agree, I believe it happens in most household at some point 🙂

I’ve been using the Facebook comment plugin until now, because my comment here always gets an error on the captcha and does not send. I love the metal toys! I’ve only ever played with one, but I didn’t know they existed until a couple years ago. They’re beautiful, and I bet they’re obviously long lasting! As a kid though, I remember loving the Tinker Toys.

Our pet rats obviously love wood toys, so we have to keep the hooman ones away from them. Otherwise, I love wood toys and don’t mind other materials. My husband tends to not like anything metal, so we don’t have any of those.

We don’t have kids, so we have no experience there. But my husband loves puzzles, and I think he tends towards wood.

I used to play with puzzle cubes a lot, since I got really good at it. I just remembered that. All of them were plastic of course.

Sounds like you’ve got a great mix of preferences in your household! Metal and wood toys each have their charm. It’s interesting how toys bring out nostalgia in all of us—Tinker Toys were such a classic!

I guess for ME the ideal product would be EPP I am a adult building block lover. I can’t see myself using wood or metal. I think for me the best option I read would be products using EPP. Not everyone’s choice I suppose but it’s my choice!

EPP is a great choice for durability and flexibility, especially for building blocks! It’s awesome that you’ve found what works best for you. What do you enjoy most about EPP compared to other materials?

Wooden toys

This article does bring up some very interesting things to think about especially when buying certain materials for children and even pets.i really have gotten into plastic brick sets and they really are nostalgic to my childhood too. I love how they are now adult inclusive with the sets for display purposes after.

As a kid I remember having wood and plastic more than anything else.

It’s interesting how wood and plastic seem to be the classic materials! Do you remember any specific toys from your childhood that stood out? I’d love to hear what made them memorable for you!

Plastic LEGO and wooden construction toys were the main features of our childhood. We also had zinc alloy toys such as matchbox toy cars. Most of these toys have remained in the family today, because of the children. Also, we still deal with LEGO toys to this day. It was passed on to children. We used to build with them. Nowadays, we play a lot of board games, cards, and wooden games, such as jenga. Or with the plastic skill building toy called Mistakos.

Wow, it’s great to hear how those toys have stood the test of time in your family! It sounds like LEGO and wooden games really have a special place. What’s your favorite memory with those toys?

For me I don’t think I’m effected by how well a toy holds up or is easy to clean. I get them based on if the item itself is what I want, and I put up with any quirks about the material. Either I’m more cautious or don’t let it get dirty. If I had kids, I’d approach their toys as “throw away” money, stuff I don’t expect to last very long. Although I’d probably be more vigilant if a material was more of a health risk, of course.

That’s an interesting perspective! It’s true, some toys are more about the fun and experience than longevity. If you had kids, what materials would you look out for when it comes to safety?

This article is great for going into the details of identifying the different type of plastic/wood/steels are and what exactly they are. I didn’t know about a handful of it and being used in toys.

Thanks!

I’m so glad you found it helpful! It’s crazy how many materials are used in toys, right? Are there any specific materials you’re now more mindful of when choosing toys for your kids?

My kids and I love wooden and metal toys.

That’s awesome! Wooden and metal toys are so durable and timeless. Do you have any favorite pieces or brands?

I appreciate how this article brings up things we may want to consider when buying toys! I suppose I feel overwhelmed at the thought of considering all of it, but it’ll probably be a good idea to be more intentional about what lasts and how to care for things made from different material, even beyond the scope of toys!

I totally get that feeling of being overwhelmed! It’s all about balance—prioritizing quality and care. Do you have any favorite materials or brands you trust when choosing toys?

Has been a great article to read!

Thanks for your kind words! I’m glad you enjoyed the article. What part did you find most interesting?