Alright, alright, it’s finally time to introduce the manufacturing process of JMBricklayer sets. Since this involves a lot of specialized knowledge, I spent a considerable amount of time digging deep and consulting with colleagues from our product department before writing this. It took a lot of effort to fine-tune the content, which is why it’s taken so long to publish this article. I hope it will answer everyone’s questions about how JMBricklayer sets are manufactured.

Without further ado, let’s dive right in!

The Design Process of Prototype

In our brick production process, prototype design is a crucial step, serving as the foundation for the entire design and production workflow. This stage allows for thorough testing and validation before moving into full-scale production.

First, the design team creates a virtual model based on initial concept drawings using specialized brick-building software. Similar to many professional LEGO MOC designers, we also utilize design tools like Bricklink Studio.

This phase primarily focuses on confirming the appearance and shape of the model, requiring the design team to engage in repeated checks and adjustments to ensure that the final design meets expectations. This process typically takes about a month, during which the design team continually refines and optimizes the model to bring it closer to the final product.

However, while this stage helps designers anticipate potential design issues to some extent, the limitations of computer simulation mean that it cannot fully replace the need for physical validation. Therefore, after the virtual model is built and initially verified, we move on to what we call the “Random Color Version” phase. In this stage, the design team constructs the model using actual brick materials. This step is not only a crucial test of the model but also the final confirmation of whether the design meets production standards.

Through this rigorous prototype building and physical verification process, we ensure that every product undergoes thorough testing and optimization before it enters production. This commitment to precision and excellence is one of the key reasons why our products have earned a strong reputation in the market.

Building the “Random Color Version” Prototype and Evaluating Structural Modifications

Image: Our Brick it Happen Project

During this stage, we conduct a physical verification of the virtual model previously designed in software, ensuring that the final product meets our standards for both appearance and functionality.

Specifically, our design team first exports a detailed list of brick components based on the software model. We then source these components and assemble a physical prototype. Once the prototype is built, we conduct a thorough evaluation, focusing on whether the appearance meets our expectations, the lighting functions properly, and the structure is sufficiently sturdy.

If the prototype passes all these evaluations, we move forward with the design process. However, if any issues are identified during this stage, we return to the software to make the necessary adjustments and optimizations. This process may be repeated multiple times until the prototype fully meets our expectations. While this might seem time-consuming, it is this iterative verification process that ensures the high quality of every JMBricklayer product.

Once we confirm that the prototype meets all standards, we integrate the lighting components and conduct another round of verification. Through this rigorous process, we guarantee that every JMBricklayer product is not only visually appealing but also flawless in functionality and stability. For us, this meticulous approach is key to standing out in the brick market and a principle we always uphold.

Applying and Modifying Colors in Design Software

Once we have completed the basic design of the prototype model, we move on to the color and pattern design phase. This process is carried out in design software, but it involves much more than simply filling the model with colors. Instead, it requires multiple rounds of discussion and iterative modifications.

Our design team adds colors and patterns to the prototype model in the software, carefully considering the strengths and weaknesses of each color scheme. We ensure that the colors and patterns are perfectly integrated into the overall design concept. Every detail—from color combinations to pattern choices—is meticulously refined to ensure that the final design not only meets our high standards but also stands out in the market.

Although this phase of repeated revisions and discussions can be time-consuming and demanding, it is a vital part of creating beautiful and unique products. Through this rigorous design process, we ensure that every product we create has the perfect visual appeal, giving it a distinct attraction and identity in the marketplace.

Building and Modifying the Software-Colored Version

This step is not just about confirming the colors; it serves as the final validation of the entire design workflow. Once we’ve confirmed the color scheme in the design software, we meticulously adjust the colors of the corresponding bricks using techniques such as painting and electroplating to ensure that each piece perfectly aligns with our design vision.

After the color adjustments are complete, we build the initial original color version, which acts as a comprehensive validation of all previous steps, from prototype construction to color design. During this process, we carefully inspect every detail, evaluating the model’s appearance, stability, and overall effect. If we identify any issues—such as unsuitable parts, unstable structures, or unsatisfactory color schemes—we immediately revert to the corresponding design steps to make the necessary adjustments.

This process may be repeated multiple times, with each iteration of modification and validation bringing our product closer to perfection. For instance, if the structure proves to be unstable, we return to the initial prototype building stage to make adjustments; if the color scheme is unsatisfactory, we go back to the color design phase to refine it. This meticulous approach ensures that every detail of our product meets the highest standards.

It is through this rigorous process of continuous refinement and strict quality control that JMBricklayer is able to deliver products that are not only durable but also visually stunning. We believe that only products that have undergone countless rounds of testing and refinement can truly earn market recognition and provide consumers with the ultimate building experience.

Steps Required Before Mass Production

This process not only ensures the high quality of our products but also lays a solid foundation for smooth production. The following are the steps we strictly follow in order.

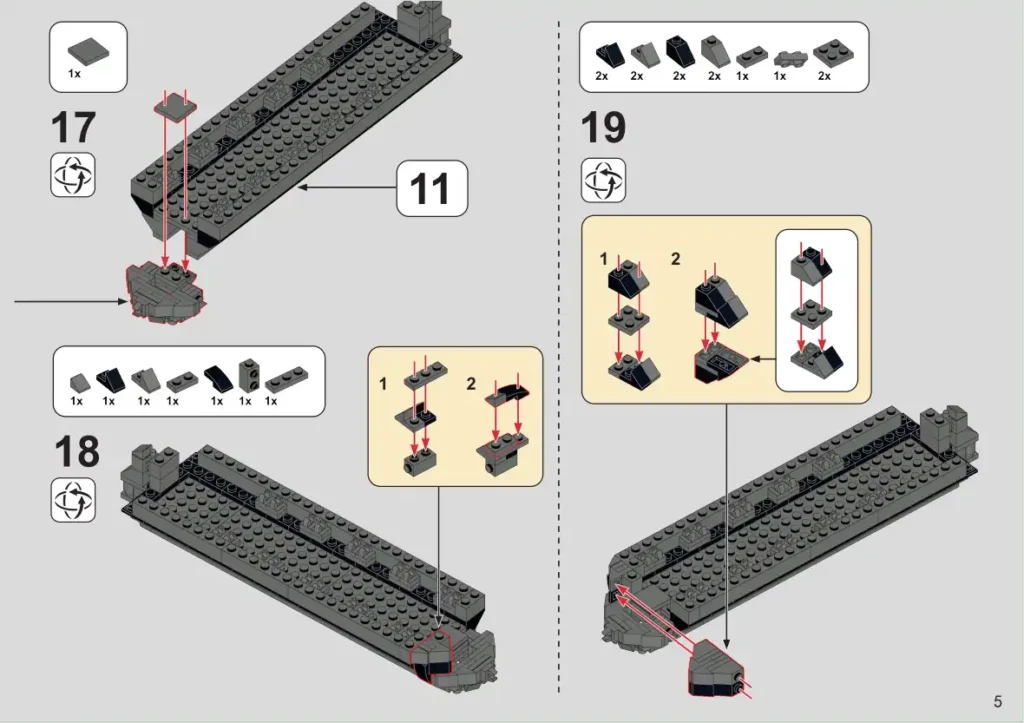

1. Create and Validate the Instruction Manual

First, we create and validate the product’s instruction manual. This step is especially critical, as the assembly steps outlined in the manual directly affect the user experience. We start by creating a digital version of the manual, and then meticulously follow its steps to rebuild the original color version of the model. If we find that certain steps are difficult to understand, particularly for beginners, we simplify those steps and add more detailed annotations. If structural or color issues are identified during this validation process, we add extra parts to a separate pack and modify the manual accordingly. This process typically requires multiple rounds of validation and adjustment to ensure the manual is both clear and accurate in guiding users through the assembly process.

2. Design Product Packaging

Once the manual is confirmed, we move on to designing the product packaging. This step not only enhances the product’s appearance and perceived value but also ensures that the product remains intact during transportation and display. Packaging design is not just the product’s exterior; it is a crucial aspect of the brand’s image, and we apply the same level of meticulous care in this phase.

3. Generate the Bill of Materials (BOM)

Next, we generate the Bill of Materials (BOM) based on the validated instruction manual. This list details all the bricks and components required to produce the product. The accuracy of the BOM is critical for the subsequent production of material packs, as it ensures that every box of the product contains all the parts needed for users to complete the build.

4. Produce Separate Packs

Finally, we produce the corresponding Separate packs based on the BOM. These packs are used for mass production, ensuring that every batch of the product meets our high standards. Through this step, we guarantee that the product has undergone comprehensive validation before it reaches the market, fulfilling consumer expectations.

Now that you’ve learned about our production process, what are your thoughts? I’d love to hear your feedback! If there’s anything else you’d like to know about our brand, feel free to share your questions or comments in the section below!

42 Responses

I really love the work put in creating new sets. It’s awesome to see the tools available to do so.

Thanks for your kind words! It’s amazing how creativity and the right tools can bring ideas to life. What’s your favorite part of the set creation process?

Lets have an article showing off fans collections and how they display it!

That’s a good idea!

Very interesting

Very nice article to read and above all interesting, I was so curious to know how you created… you did an excellent job and I am convinced that you will always improve… I will be your loyal fan 🤩

Thank you so much for your kind words! I’m thrilled you enjoyed the article. I’m always striving to improve, and your support means a lot. Feel free to share your thoughts or questions

I completely agree with both approaches. Design software is undoubtedly a valuable tool, providing a digital canvas to experiment and iterate. However, there’s no substitute for the tactile experience of working with physical materials. Hands-on design allows for a deeper understanding of how pieces interact, fit together, and ultimately, how the final creation will stand and appear. This is especially crucial when dealing with irregular shapes that don’t conform to standard blocks or rectangles. Only by physically manipulating these elements can one truly grasp their potential and how they contribute to the overall design.

Absolutely! The tactile aspect is key—feeling how pieces connect in real life offers insights that software can’t. Have you found any specific challenges when transitioning from digital to physical design?

Nothing right at the moment, but I have only really tried with regular rectangle and square bricks or the most part, guess I’m playing it very simple and cautious.

I have always had a blast using the digital design studio software to recreate plenty of pixelated designs. What I find very interesting is that the colors may not be always at hand to build exactly what I want. However, I can build the design in a mixture of colors to see it in person and use the software to use the real or nearest color I prefer to use.

Hey, that’s why manufacturing comes into play! However, doing the random color version is always interesting.

This is really cool to see the behind the scenes from the beginning. Thanks for sharing this information!

Thank you! I’m glad you enjoyed the behind-the-scenes look. What part of the process stood out to you the most?

Well written. Very impressive from the concept to the ready for sale build! This bit of knowledge makes my builds more meaningful!

I appreciate every JMB employee! Wow! Kudos to all of you!

Thanks for doing what you do. You provide joy to millions of people!

Thank you so much for your kind words! We’re thrilled that our work adds value to your builds. What projects are you working on right now? We’d love to hear more about how you’re enjoying the process! 😊

I’ll be working on Interstellar Archives 70111 once they get through the days of processing my order? Hopefully it will ship soon. Yeah patience is hard to handle when the excitement and anticipation is so high.

Then the real excitement…Steampunk Marble Run. So looking forward to see and feel the build. My mind is in a sweet spot when building.

Truly appreciate all the talent at JMB. Impressive business model and additionally a great hobby for millions!

Thanks again for what you do.

Thank you for your kind words! We totally get the excitement—Interstellar Archives is worth the wait! The Steampunk Marble Run will be a blast to build.

When seeing sets sold by Chinese manufacturers, you often see identical sets sold by different companies. Is this because the various companies only buy the non-exclusive rights to the model and produce them independently or is there a single company that produces them and then they are purchased by retailers and packaged with different brands?

Yes, it’s true that different brands often select sets they believe have potential within the industry to test market preferences. They do this to find inspiration and direction for their new designs. That’s why you might see the same set being sold by different brands.

Very interesting about creation of 3d model and colour choice.

I MEAN THERE IS SO MUCH WORK BEHIND A model!!!!

Absolutely! It’s incredible how much effort goes into each step, from the initial design to color adjustments. What part of the process do you find most fascinating?

The Design Process of Prototype and modification of the 3d model

It has been such a joy to finally read this article.

I’m so glad you enjoyed the article! What aspects stood out to you the most? It would be great to hear more about your thoughts and what resonated with you!

The article was very informative as to how sets are designed and created, It seems like there is a lot of work involved, so all the hard work from JMBricklayer is very appreciated!

Thank you for your kind words! Indeed, a lot of effort goes into every detail to ensure top-notch quality. We’d love to hear your thoughts on any specific sets or design aspects that caught your attention!

Its amazing to see this whole process. I always wondered how much went into this process.

Thanks for the kind words! It’s indeed a complex yet rewarding process. If you’re curious about any specific part, feel free to ask!

I honestly didn’t think about how boxes were designed and thatd cool too!

Absolutely! Box design is fascinating and often overlooked. It’s amazing how much thought goes into making it functional and appealing. What do you think is the most important aspect of good packaging design?

If I could start my career over I would love to figure out how to design these toys!

That sounds like an exciting path! Have you explored any design tools or communities to get started? It’s never too late to dive into the world of toy design—lots of resources are available online!

It’s fascinating to see the detailed process behind the creation of JMBricklayer sets! The attention to detail in both the virtual and physical prototyping stages is impressive

Absolutely! The design process truly highlights the craftsmanship involved. Which part of the process stood out to you the most? It’s interesting how every step contributes to the final product’s quality.

It would be interesting to see a behind-the-scenes video of the design and prototyping process

Thanks for the suggestion! A behind-the-scenes video would definitely give more context to the design journey. What specific aspects are you curious about? We’d love to dive deeper into those details!

How long does the entire process from design to production typically take for a new set?

at least hafl a year.

It was a very impressive look at the behind the scenes of your company. I knew your company was top knotch

Thank you! We’re glad you enjoyed the behind-the-scenes look. We always strive for excellence. What aspects of our process stood out to you?

I can only imagine how much fun folks have making these dreams come true. The folks behind the scene. And the folks in front. This must be a really fun job! Bringing joy to world!